Supply Chain: How Generic Drugs Get to You and Why It Matters

When you pick up a generic pill at the pharmacy, you’re not just getting a cheaper version of a brand-name drug—you’re receiving the end result of a complex, high-stakes supply chain, the network of manufacturers, distributors, and regulators that move medicines from factories to patients. Also known as the pharmaceutical supply chain, it’s the invisible system that decides whether your medication is in stock, out of reach, or dangerously delayed. This isn’t just about cost. A broken supply chain can mean no insulin, no antibiotics, or no blood pressure pills when you need them most.

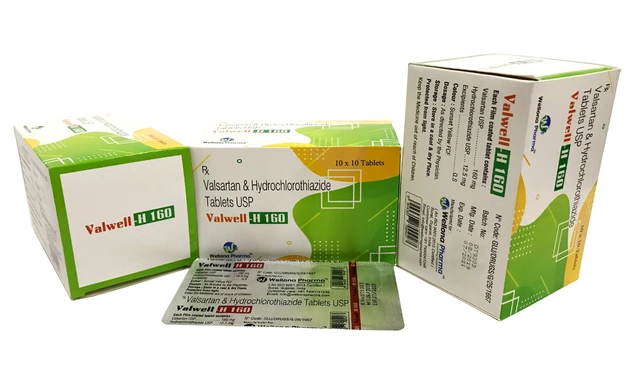

The generic drug distribution, the process of moving low-cost versions of branded drugs to pharmacies and hospitals runs on razor-thin profits. That’s why efficiency isn’t optional—it’s survival. A single factory in India or China can supply millions of tablets, but if one machine breaks, or a shipment gets held at customs, or a raw material runs short, the whole chain stumbles. The supply chain efficiency, how well each step—from sourcing ingredients to delivering pills—minimizes waste and delays directly affects how often you hear about drug shortages. And yes, those shortages aren’t random. They’re predictable, often caused by over-reliance on one supplier, outdated inventory systems, or lack of backup plans.

It’s not just about moving boxes. The pharmaceutical supply chain, the end-to-end flow of medications from production to patient includes regulators like the FDA, who inspect factories; wholesalers who store drugs in climate-controlled warehouses; and pharmacists who track expiration dates and reorder before stock runs out. When any of these pieces fail, patients pay the price. That’s why the FDA’s MedWatch system and the Orange Book aren’t just paperwork—they’re safety nets built into the system. Even small things, like how long a pill stays in a warehouse before shipping, can affect its potency. And when manufacturers cut corners to save pennies, the risks ripple outward.

What you’ll find in the posts below isn’t just theory. These are real stories from the front lines: how data and tech are fixing bottlenecks, why some generic drugs keep disappearing, how a single factory shutdown can trigger nationwide shortages, and what patients can do when their meds aren’t available. You’ll see how supply chain decisions—made far from your local pharmacy—directly impact your health. This isn’t logistics jargon. It’s about whether you get your next prescription on time, safely, and without surprise price hikes. These articles show you how the system works, where it breaks, and what’s being done to fix it.

International Supply Chains: Why Foreign Manufacturing Is Causing Drug Shortages in 2025

International supply chains for pharmaceuticals are under strain, causing widespread drug shortages in 2025. Over 80% of active ingredients come from China and India, making the system vulnerable to disruptions. Here’s how it’s happening-and what’s being done to fix it.