Since 2018, a quiet but dangerous problem has shaken the generic drug industry: nitrosamine contamination. These aren’t just chemical byproducts-they’re potent carcinogens found in pills millions of people take daily. What started with a recall of blood pressure medication has grown into a global crisis affecting antidepressants, diabetes drugs, heartburn treatments, and more. The FDA has pulled over 40 specific products off shelves and issued more than 500 recalls tied to nitrosamines. For patients, the question isn’t just whether their medicine works-it’s whether it’s safe.

What Are Nitrosamines and Why Do They Matter?

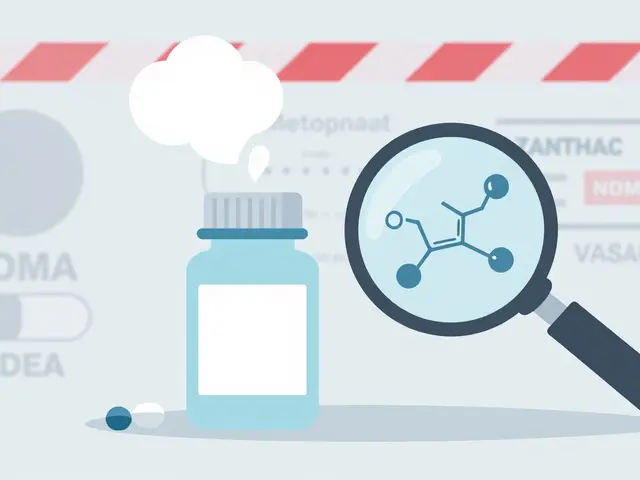

Nitrosamines are a group of chemicals that form when certain amines react with nitrites under heat, pressure, or specific pH conditions. They’re not added intentionally. They sneak in during manufacturing, storage, or even through packaging materials. The most common ones found in drugs include NDMA (N-Nitrosodimethylamine), NDEA (N-Nitrosodiethylamine), and newer ones like N-nitroso-varenicline and N-nitroso-duloxetine-collectively called NDSRIs (nitrosamine drug substance-related impurities).

The problem? Even tiny amounts can raise cancer risk. The FDA sets acceptable intake limits based on lifetime exposure. For NDMA, it’s 96 nanograms per day. For NDEA, it’s just 26.5 ng/day. That’s less than a grain of salt in a bathtub of water. But if you’re taking a pill every day for years, those nanograms add up. The International Agency for Research on Cancer classifies most nitrosamines as probable or possible human carcinogens. That’s why regulators didn’t wait-they acted fast.

Which Drugs Were Affected?

The first big hit came in 2018 with contaminated valsartan, a common blood pressure drug. Soon after, losartan and irbesartan followed. Then came ranitidine (Zantac), pulled from shelves worldwide after tests showed it could form NDMA inside the body. Metformin, the go-to diabetes medication, saw recalls in 2020. Duloxetine (Cymbalta generics), varenicline (Chantix generics), and even rifampin-an antibiotic used for tuberculosis-were later found to contain nitrosamines.

It wasn’t just active ingredients. Packaging materials became a major source. Blister packs, bottle liners, and adhesives containing secondary amines started showing up as culprits. One 2024 FDA case study found that a generic antibiotic tablet exceeded safe limits by more than 15 times-all because of a nitrosating agent in the packaging film. This meant manufacturers couldn’t just fix the API. They had to redesign the whole product: from how it’s made to how it’s stored.

How the FDA Responded

The FDA’s approach has been aggressive, detailed, and constantly evolving. In 2020, they published initial guidance. In 2023, they released a major update that required compound-specific limits for NDSRIs-something the European Medicines Agency hadn’t yet mandated. Each impurity got its own safe threshold. For example, N-nitroso-duloxetine has a limit of 96 ng/day, while N-nitroso-varenicline is also capped at 96 ng/day. But if a drug contains more than one nitrosamine, the total exposure can’t exceed 100% of the combined risk.

Manufacturers were told to test using ultra-sensitive LC-MS/MS methods capable of detecting nitrosamines at 0.3-3 ng/mL. They had to map every possible formation pathway: from raw materials to reaction conditions to storage. Many spent over $2 million and 18 months just to fix one product line.

By August 2025, the FDA planned to enforce full compliance. But in June 2025, they changed course. Instead of demanding perfect solutions by a hard deadline, they now accept detailed progress reports. Companies must document their mitigation efforts in annual or amended annual reports. This wasn’t a surrender-it was a recognition that the science and supply chains were too complex for a one-size-fits-all deadline.

Global Differences in Response

The U.S. moved fastest. The European Medicines Agency (EMA) has issued 32 recalls through mid-2025, but with a more flexible timeline extending into 2026. Health Canada, the UK’s MHRA, and Japan’s PMDA have each handled between 5 and 15 recalls. The FDA’s stricter NDSRI limits and faster enforcement created pressure that smaller manufacturers struggled to meet.

One key difference: the FDA requires proof of control for every specific nitrosamine, while some other agencies allowed broader, less detailed controls. This means U.S. manufacturers face higher testing costs and longer reformulation cycles. But it also means fewer surprises down the road. A manufacturer in Brazil recalled a generic metformin in 2024 because their testing method missed NDEA. The FDA’s method caught it early.

Real-World Impact on Manufacturers

Small generic drugmakers are being squeezed. Testing programs now cost $500,000 to $2 million per year. Many don’t have in-house labs. They rely on third-party labs, which are backlogged for months. One manufacturer in Ohio spent 14 months replacing a single excipient supplier after discovering that magnesium stearate from that vendor introduced nitrites, leading to NDEA formation in three different ARB products.

On Reddit, a process engineer wrote about spending 18 months and $2 million to fix their metformin line. They thought they’d solved the problem-until a new nitrosamine appeared in a different step of the process. “We fixed one thing and broke another,” they wrote. “It took three redesigns before we got it right.”

Companies that acted early survived. One firm identified nitrosamine risk during development and switched excipients before launch. No recall. No lost sales. They gained FDA trust-and faster approval for future products.

Meanwhile, bigger players like Teva, Fresenius Kabi, and Sun Pharmaceutical built dedicated nitrosamine task forces. They hired organic chemists, analytical scientists, and packaging engineers. They invested in real-time monitoring systems. Now, they’re not just compliant-they’re market leaders.

What This Means for Patients

If you take a generic drug, you’re not at immediate risk. The FDA doesn’t recall drugs unless levels exceed safety thresholds. But the crisis has caused shortages. Between 2018 and 2020, 15-20% of ARB products were temporarily unavailable. Patients switched brands or waited weeks for restocks.

There’s also a psychological toll. People who’ve been taking metformin for years now wonder: “Is mine safe?” The answer isn’t always clear. Not every batch is tested. Not every lot is public. The FDA posts recall notices, but they’re buried in databases. Most patients don’t check.

What you can do: Check the FDA’s recall database if you’re on a drug that’s been flagged. Ask your pharmacist if your generic has been reformulated. Don’t stop taking your medicine without talking to your doctor. The risk of uncontrolled high blood pressure or diabetes is far greater than the risk from trace nitrosamines.

The Future: More Testing, More Costs, More Change

Nitrosamines aren’t going away. The FDA has signaled this is a long-term priority. Experts predict testing will expand to more drug classes-possibly including antivirals, antifungals, and even over-the-counter products. The agency is already studying nitrosamine formation in proton pump inhibitors and beta-blockers.

Manufacturers will keep investing. But with generic drug prices under constant pressure, the cost of compliance is eating into profits. Evaluate Pharma estimates the industry’s margins have dropped 3-5 percentage points since 2018. Smaller companies are selling out. Consolidation is accelerating.

The real win? Safer drugs. The system is far from perfect. But because of this crisis, the industry now tests for impurities it once ignored. Quality systems are stronger. Transparency is improving. And for the first time, regulators and manufacturers are treating contamination risks with the seriousness they deserve.

Are all generic drugs at risk of nitrosamine contamination?

No, not all generics are affected. Only specific drugs manufactured under certain conditions have shown contamination. The FDA has identified over 500 recalls tied to nitrosamines, but these represent a small fraction of the thousands of generic drugs on the market. Most generics are safe. If your drug hasn’t been recalled or flagged by the FDA, there’s no reason to assume it’s contaminated.

How can I check if my medication has been recalled?

Visit the FDA’s Drug Recalls page and search by drug name or manufacturer. You can also ask your pharmacist-they’re required to notify you if your prescription is recalled. Some pharmacies send automated alerts. Don’t rely on news reports alone-recalls are often updated, and not all media outlets track them accurately.

Can nitrosamines be removed from contaminated drugs?

No, once nitrosamines are formed in a finished product, they can’t be filtered out. That’s why recalls happen. The solution is prevention: reformulating the drug, changing suppliers, adjusting manufacturing conditions, or switching packaging materials. The goal isn’t cleanup-it’s stopping contamination before it starts.

Why did the FDA delay the August 2025 deadline?

The FDA realized that many manufacturers, especially smaller ones, needed more time to identify root causes and gather stability data for reformulated products. Some nitrosamine pathways took over a year to fully understand. The delay isn’t a relaxation of standards-it’s an acknowledgment that fixing complex chemical problems takes time, resources, and testing. Progress reports are now required instead of full compliance by the deadline.

Should I avoid generic drugs because of this issue?

No. Generics are still safe, effective, and critical to affordable healthcare. The nitrosamine issue affects a small number of products, and the FDA’s response has made the system more rigorous. Switching to brand-name drugs won’t solve the problem-some brand-name drugs were also recalled. The key is staying informed, checking for recalls, and talking to your doctor if you’re concerned.

Brenda King January 22, 2026

Just checked my metformin bottle - no recall notice. Still taking it. Don't panic, people. The FDA isn't sleeping. If your pill's on the list, you'll know. If it's not, you're fine. 😊

Lana Kabulova January 24, 2026

Wait - so they're saying trace amounts are dangerous but only if you take them daily for decades? That's like saying a single raindrop can flood your house if it falls every minute for 30 years? I get the science, but the fear-mongering is wild. And why is no one talking about how this is making generics unaffordable? The real villain isn't nitrosamines - it's the profit-driven system that lets this happen in the first place

Liberty C January 26, 2026

Oh please. You people act like this is some new revelation. Nitrosamines have been in processed meats since the 1970s. The fact that we're losing our minds over a few nanograms in pills while ignoring the carcinogenic sludge in your Big Mac is peak modern hypocrisy. The FDA's 'aggressive' response? A PR stunt. The real issue is that generic manufacturers are outsourcing to labs in countries where 'quality control' means 'hope for the best.' And don't get me started on blister packs - those are basically chemical time bombs wrapped in plastic with a smiley face. 🤡

shivani acharya January 26, 2026

They're lying. All of them. The FDA, the pharma giants, your doctor - they're all in on it. Nitrosamines are a cover for something bigger. Did you know that the same companies that make these drugs also own the testing labs? And the packaging? Owned by the same conglomerate. They're deliberately letting tiny amounts slip through to keep you dependent - because if you stop taking your meds, you might actually get healthy. And then who'd buy their $400/month pills? I've been on metformin for 8 years. My blood sugar's fine. I'm convinced it's the nitrosamines keeping me alive. Yeah. You heard me. 😈

Keith Helm January 27, 2026

Regulatory timelines must be calibrated to technical feasibility. The FDA's shift to progress reporting reflects a pragmatic recalibration of enforcement priorities.

Daphne Mallari - Tolentino January 28, 2026

It is deeply concerning that the general public has been so poorly educated on the nuances of impurity thresholds. One does not simply equate 'detectable' with 'dangerous.' The FDA's limits are based on probabilistic carcinogenicity models - not anecdotal fear. To conflate this with systemic negligence is intellectually lazy and emotionally manipulative. The industry has responded with unprecedented rigor. We should applaud the transparency, not vilify it.

Neil Ellis January 28, 2026

Look, I get it - this stuff is scary. But think about it: we're talking about people who need their blood pressure meds to stay alive. They're not choosing between safety and cost - they're choosing between life and death. The fact that manufacturers are finally being held to a standard that actually protects people? That's a win. Yeah, it's messy. Yeah, it's expensive. But we're finally treating medicine like it matters - not just like a commodity. Let's not lose sight of that.

Alec Amiri January 29, 2026

So let me get this straight - a guy in Ohio spent $2 million and 14 months to fix one excipient, and now the FDA says 'eh, just send us a report'? That's not progress, that's surrender. And the people who can't afford to fix their stuff? They're getting shut out. This isn't about safety - it's about who gets to play in the game. The big boys win. The little guys? They disappear. And you think that's okay?

Rob Sims January 30, 2026

Oh wow, the FDA 'changed course'? Yeah, because they realized they couldn't force tiny companies to do lab work that costs more than their entire annual revenue. This isn't a win for safety - it's a win for big pharma. Now only the corporations can afford to play. The rest? They either fold or sell out. And you call that 'progress'? Please. This is how monopolies are born - under the banner of 'public health.'

arun mehta February 1, 2026

As someone from India, I see this daily - our local pharmacies stock generics made in factories that barely have clean rooms. But here’s the thing: the real heroes are the engineers who spent years fixing these problems. One lab in Pune redesigned their entire drying process to avoid nitrosamine formation - no recall, no drama. They didn’t wait for regulators. They just did it. That’s the spirit. Let’s celebrate the quiet fixers, not just the loud critics. 💪🌍